We produce various civil,industrial and commercial Motor Valves for Smart Gas Meter (G1.6~G40) suitable for various manufacturers.The motor valves have fine properties as good sealing, durability and explosion-proof performance, immersion resistance, salt spray resistance, low power consumption, short switch time,etc. And our products have passed the European DVGW explosion-proof certification, A-tex, IECEx explosion-proof certification and national valve quality supervision and inspection center certification, woning the praise of the domestic market.

|

Working Medium |

Natural Gas |

|

Flow-rate Range |

0~6m³/h |

|

Pressure Loss |

≤20Pa(6 m³/h) |

|

Working Pressure Range |

0~50kPa |

|

Max. Pressure |

75kPa |

|

Operating Temperature |

-25℃~55℃ |

|

Storage Temperature |

-25℃~60℃ |

|

Relative humidity |

≤95%RH |

|

Durability |

≤15 Years (No Fault or Damage after consecutive 5000-times cycle) |

|

Leakage |

Under 5kPa, leakage≤0.1L/h |

|

Operating Voltage |

DC2.8V ~3.6V |

|

Avg current |

≤35mA (3.6v) |

|

Opening Valve time |

9±0.5s(3.6v) |

|

Closing Valve time |

|

|

Peak Current (Motor Start-up) |

≤105mA (3.6V) |

|

Gas Meter Application |

G1.6/G2.5/G4 Gas Meter |

|

Structural support |

Body material is POM,valve sealing material is NBR |

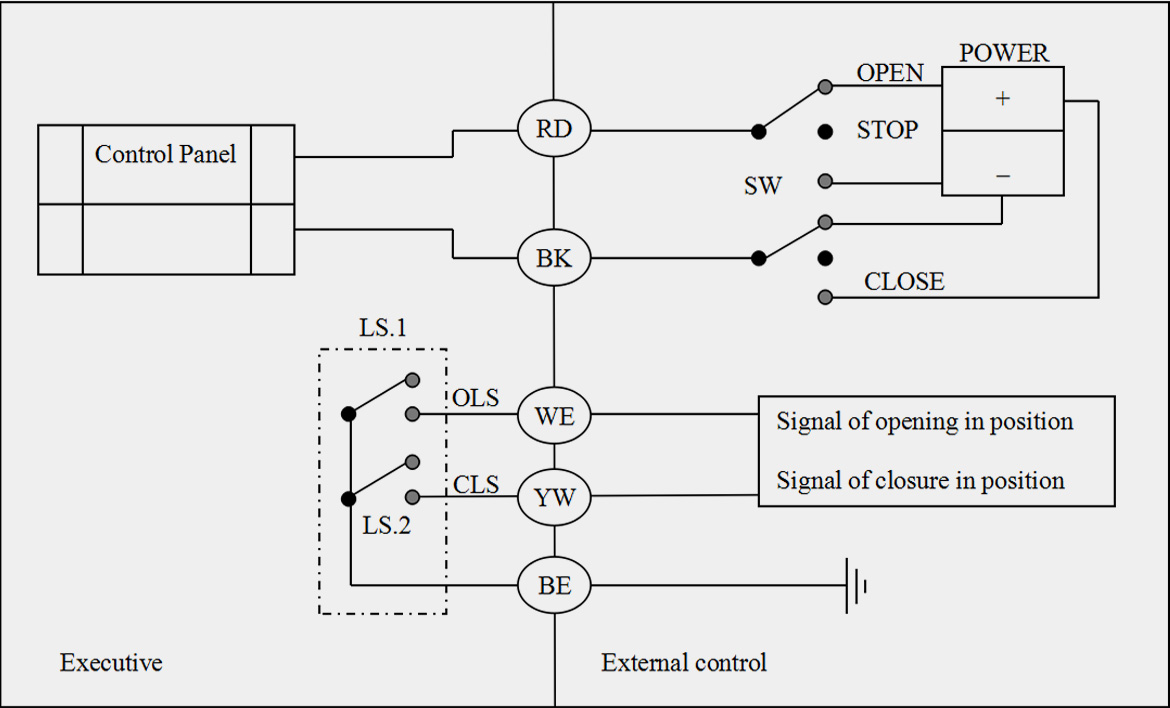

2. Instruction

1、The ball valve is driven by the motor drive mechanism, and then driving the ball to achieve opening / closing valve.

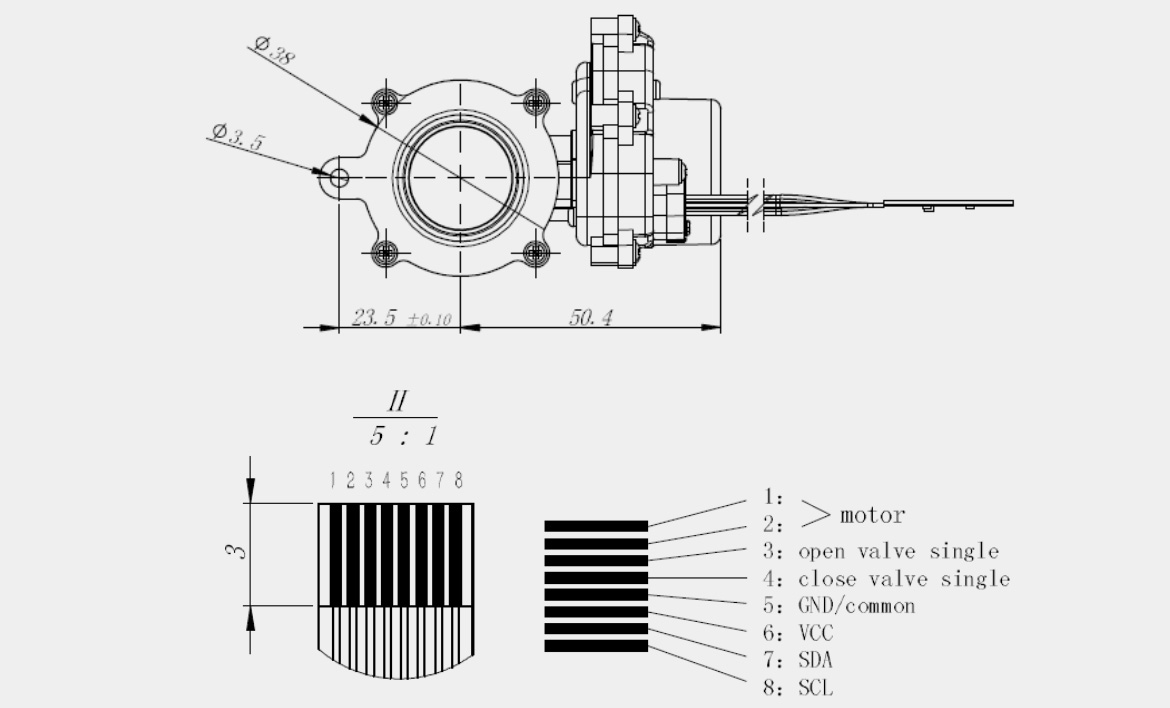

2、This valve has 5 control wires, of which red / black is the motor wire and yellow/white/blue wires are for indicating switch state wire.

3、Valve opening process: when red wire connects “-” pole and black wire connects “+” pole, detecting the blue and white wire are connected, then the opening valve is completed.

4、Valve closing process: when red wire connects “+” pole and black wire connects “-” pole, detecting the blue and yellow wire are connection, then the closing valve is completed

5、If wire is extended by connectors, opening/closure procedures follows the same manner.

Illustration:

1.SW connects to the power, LS.1 power up after valve opens in position, control panel postpones power supply by 300ms and power off, valve stays open.

2.SW connects to the CLOSE, LS.2 power up after valve closes in position, control panel postpones power supply by 300ms and power off, valve stays close.

6、The voltage of valve both ends shall not be less than 2.5V

7、The driving current of valve control circuit provided cannot be less than the motor peak current.

8、If the parameters and structure of this internal valve changes, our company will promptly inform your company.

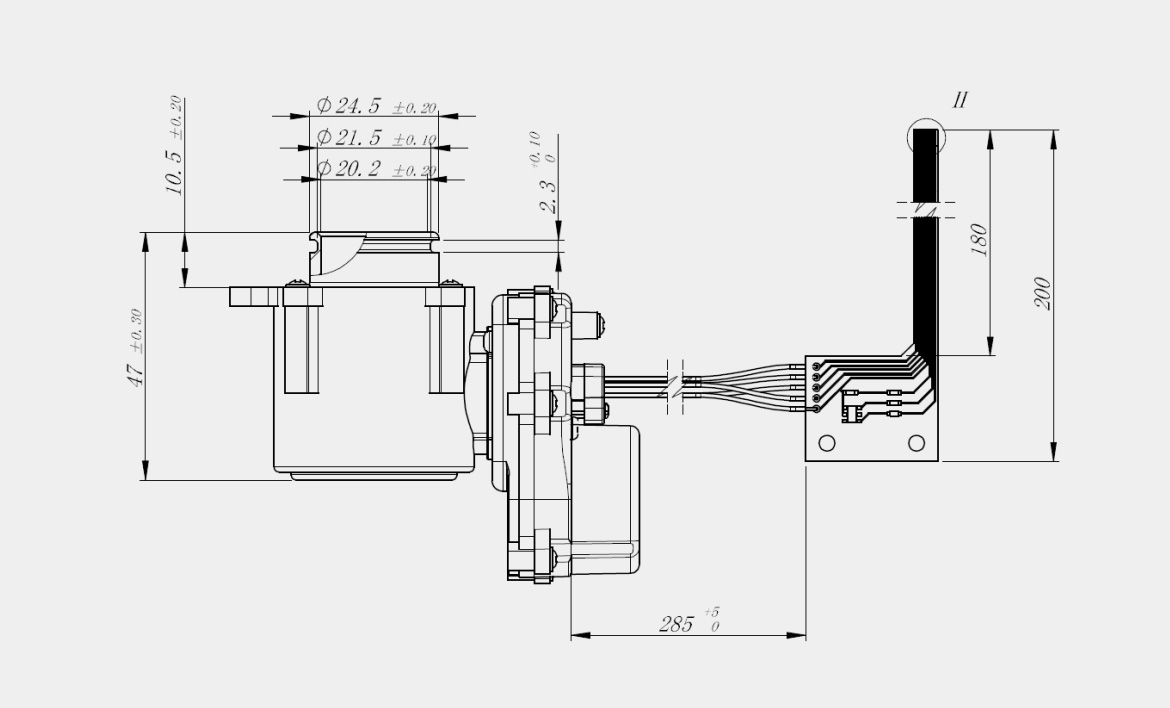

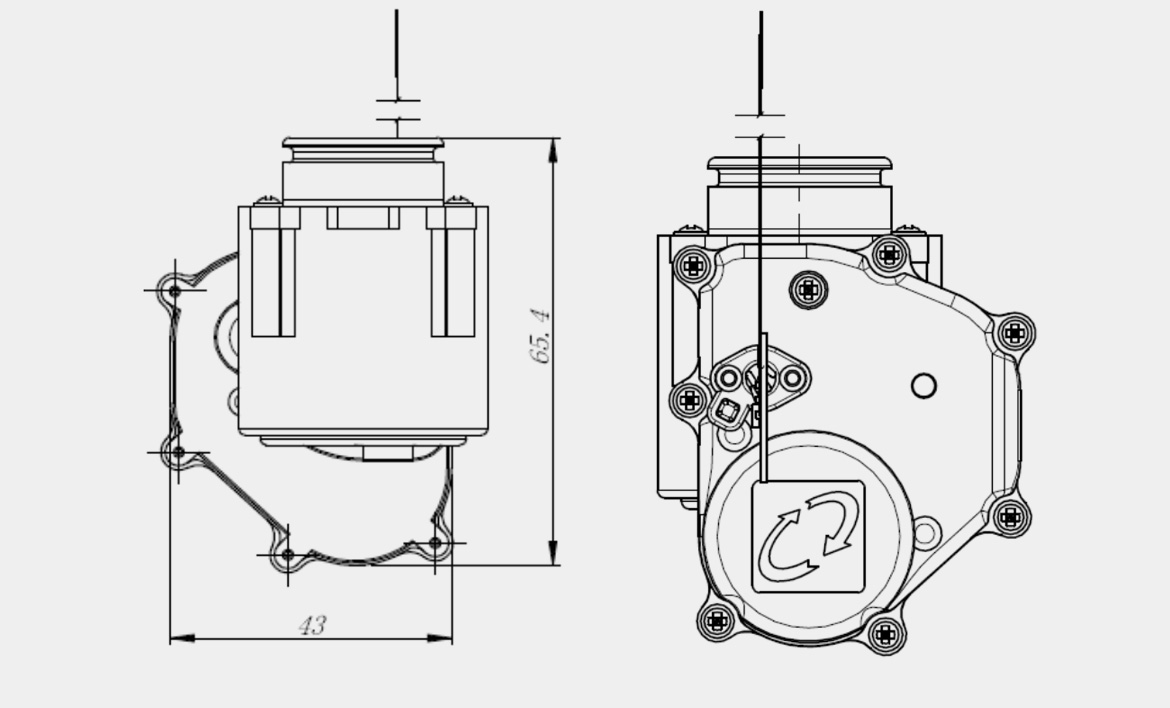

3.Drawings

a.Key technologies:

- Dividing the ball valve into a valve unit and a drive unit for controlling the opening and closing of the valve unit make it convenient to manufacture;

- an accommodating groove is installed on one side of the inner wall of the valve body,One side of the outer wall of the valve body is provided with a groove on the accommodating grooves which an accommodation space that extend inward corresponds to, and one end of the valve rod is disposed in the groove through the accommodating grooves, and the other end is connected with the driving unit; stop collar and the elastic elements are matched and installed at the inlet or the outlet of the valve body with more accurate ball body position. moderate opening and closing force, which is safe and reliable;

- The elastic mechanism is installed in the valve body to limit the contact area and compression of the ball and sealing element. Even if it is subjected to dimensional changes caused by different temperatures, it will not leak with good sealing effect, small friction and low power consumption.

b.Main parameters:

Working medium: natural gas, liquefied petroleum gas;

Flow range: 0~6m3/h

Operating voltage: 2.8 to 5.5V;

Operating current ≤80mA

Opening time: ≤5S; Closing time: ≤5S

Working life: 10,000 times;

Service life: ≤12 years

c.Advanced Technology (characteristics):

- Overcoming other products’ problem that the friction coefficient of rubber sealing elements is large;

- The principle of spring compression is adopted, which has an anti-lock function after lubricating oil failure;

- Critical components will not leak due to dimensional changes at high and low temperatures,ensuring product reliability;

- Use bidirectional switch signal control to make the switch in place without damage when it faces impact.

Patent No.: ZL201320751574.3